What is Profibus-PA and How Does it Differ from Profibus-DP?

After reading this article, you’ll not only be able to explain the Profibus-PA like a pro, you’ll understand exactly how different it is from the Profibus-DP.

So, let’s get started. What is Profibus-PA? In the video below, you’ll see Profibus-DP vs PA.

This is a factory. Typically, in a factory, you have two key areas:

– There’s the control room which houses several industrial computers;

– And there’s the factory floor, where you’ll find a number of sensors.

One of the most common industrial computers you’ll see in a control room is called a programmable logic controller also known as a PLC.

The PLC’s job is to control the process of manufacturing the end product in the factory. A PLC does that by monitoring the sensors.

The sensors, which measure conditions like pressure, temperature, and levels, can be found anywhere along the manufacturing line on the factory floor, and those sensors can be located quite a distance from the control room.

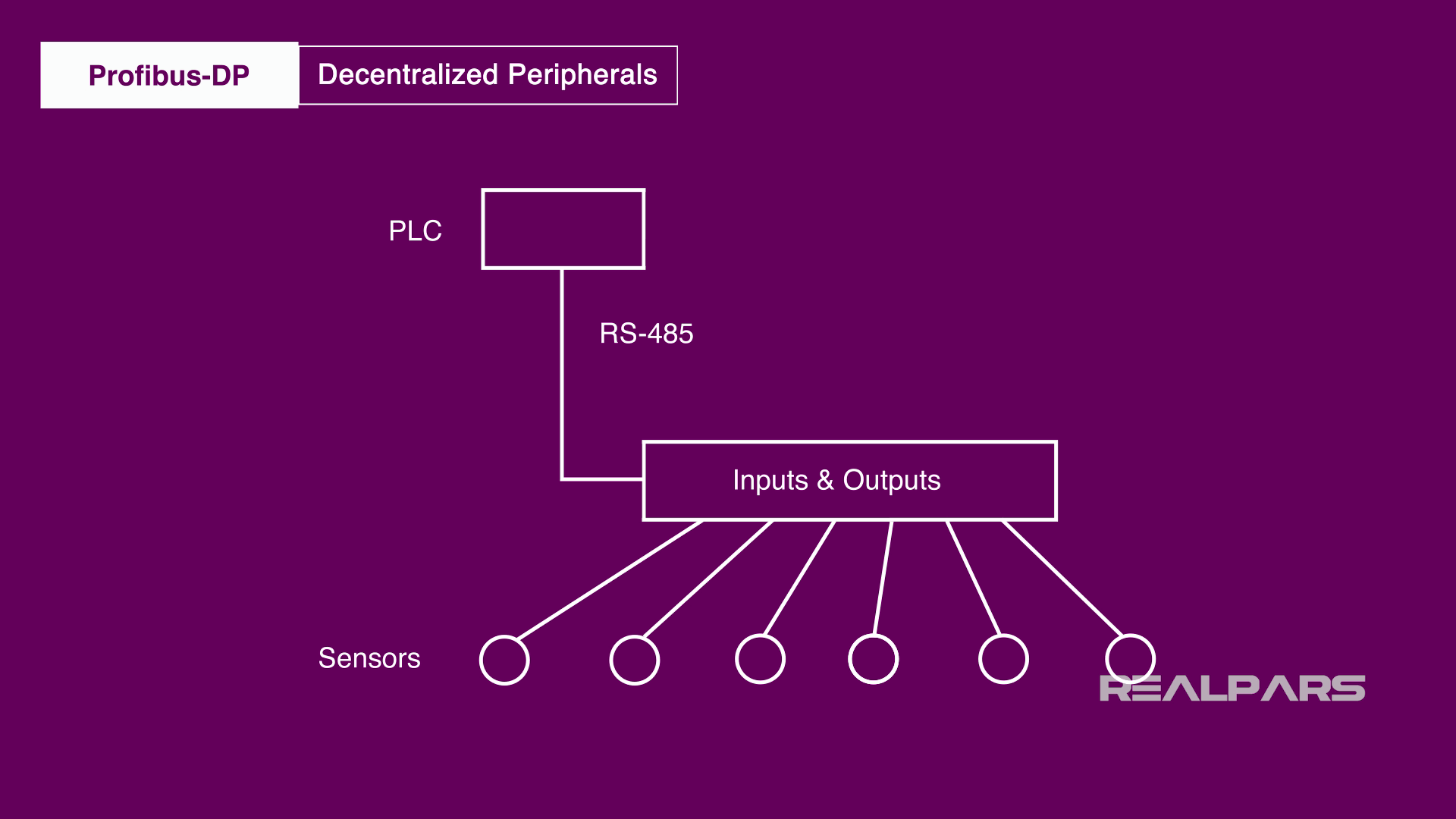

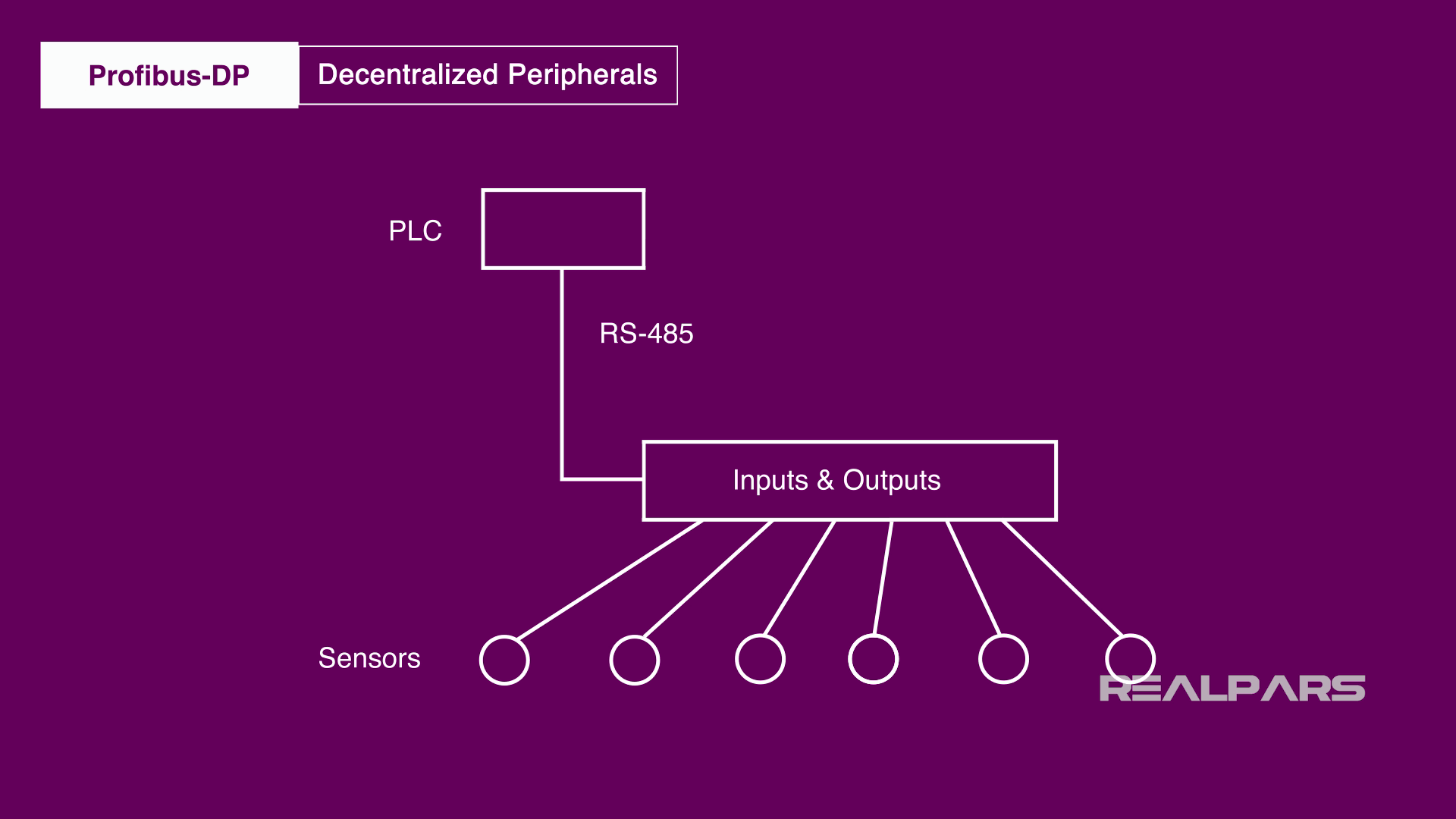

Profibus-DP

So how would you ensure a PLC could successfully monitor all those factory sensors?

Well, you could use cables to connect each PLC’s input and output directly to each sensor.

But here’s the snag in that solution: In large factories, there’s often a long distance between the control room where the PLC is installed, and the factory floor where the sensors are installed.

Doing it that way, you’re going to end up with a massive number of cables running between the control room and the factory floor. Not only is that expensive…it’s not very efficient.

The better way is to use the Profibus-DP and here’s why…

Profibus-DP allows you to move the PLC inputs and outputs to the factory floor and connect them to the sensors. You can connect the I/Os to the PLC using a single RS-485 cable.

Then use shorter cables to connect the I/Os to the sensors…and then use a single cable to connect the same I/Os to the PLC on the other end. The setup is far cheaper and much more efficient.

A little background on the name Profibus-DP

The DP stands for Decentralized Peripherals.

Before Profibus-DP, the I/Os, or peripherals as they are also known, were centralized in the control room.

But by moving them to the factory floor next to the sensors, we decentralize these I/Os or the peripherals, hence the DP designation. So that’s why we call this type of Profibus, Profibus-DP.

Profibus-PA

Sometime after the Profibus-DP was developed, a creative bunch of automation engineers had an idea: What if we could get rid of the cables as well and make this network even more efficient?

And that’s how Profibus-PA was invented.

PA is short for Process Automation.

Profibus-PA allows you to remove this I/O unit and also the cables and replace them with a segment coupler and a single Profibus-PA cable.

With the new setup, instead of connecting the sensors to the I/Os one by one, you can connect all of them to a single Profibus-PA bus.

On the other side of this bus, the segment coupler works to convert the Profibus-PA signal to the Profibus-DP signal. So, by utilizing Profibus-PA, you can have an even more economical and more efficient network structure.

Why Use a Segment Coupler?

Now you may be asking, why do I need this segment coupler or converter here? Can’t I just connect the Profibus-PA directly to the PLC?

Well, the short answer is no. Why? Because the PLC doesn’t have a Profibus-PA port on it.

The good news is though, that most PLCs do have a Profibus-DP port, so by utilizing this segment coupler or convertor, you can use Profibus-PA in the old systems as well.

By doing this, you actually end up with a Profibus-PA before the converter and a Profibus-DP after.

Summary

So, let’s summarize how these two industrial communication protocols have changed the ease and efficiency of setting up PLC controls.

With the invention of the Profibus-DP, we were able to advance from having the PLC in the control room directly connected to the sensors on the factory floor; to decentralizing the I/Os and moving them next to the sensors, and then using a simple RS-485 to connect the I/Os to the PLC.

Then, with the help of the Profibus-PA, we made the network even more efficient by removing the I/Os and the cables, and replacing them with a single Profibus-PA bus and a segment coupler or a convertor. Very simple!

Ok, that’s it for this article. If you have any questions regarding Profibus-DP or Profibus-PA, feel free to put them in the comment section below.

I promise you, they will be answered, and not just by anyone! Our RealPars automation engineers, all with more than 20 years of experience, really do read each and every comment and answer them promptly with very detailed and comprehensive replies.

Trust me, you won’t find that kind of responsiveness or educational value anywhere else on the internet! That’s the RealPars advantage.

Want to Learn More?

You can gain instant access to a large number of exclusive RealPars courses covering a variety of industrial automation topics, including PLC and HMI programming, DCS, IIoT, and others, all for a small yearly membership fee.

It’s an amazing value for some really robust content and lots of support. And you’ll be getting the same course work that would cost you a few thousand for one week of offline training!

All of us on the RealPars team look forward to helping you continue to advance your PLC expertise, and your career!

Got a friend, client, or colleague who could use some of this information? Please share this article.

The RealPars Team

Learn from

Industry Experts

With a 7-day trial, then €25/month